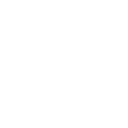

HEROSE offers reliable technological solutions for the entire hydrogen value chain

Big plans cast their shadows ahead: the transformation to a hydrogen economy is becoming more and more evident in Germany – numerous projects are in the planning stage or already being implemented. The demand for green hydrogen in Germany will be between three and six million tonnes per year by 2030. HEROSE has done its homework and offers products for all aspects of the hydrogen value chain.

Safety valves for Electrolysers type 06012, 06383, 06440, 06850

Valves for liquid hydrogen Globe valve type 11C01, 01272, 01741, Safety valve type 06383, 06440, 06800

Safety valves für compressed hydrogen type 06810, 06820, 06850

Energy revolution with hydrogen

The course has been set; the German government and the European Commission want to be pioneers in the use of hydrogen, and the focus will be on green – i. e. climate-neutral – hydrogen. The production of green hydrogen is set to increase over the next few years, so that in the long term hydrogen can be produced in system-relevant quantities. The technologies for this are available. The task now is to build up a functioning infrastructure so that hydrogen can become a core element of the energy transition.

Although hydrogen is the commonest and simplest element in the universe, it mainly exists in chemical compounds. Hydrogen is obtained by splitting water (H2O) into oxygen (O) and hydrogen (H2) – if this splitting is done with the help of electric current, it is called electrolysis. Green hydrogen is obtained if the electricity for this originates from wind power or solar energy.

Production using electrolysis

Four technologies are distinguished in electrolysis: Alkaline Electrolysis (AEL), Proton Exchange Membrane Electrolysis (PEM), Anion Exchange Membrane Electrolysis (AEM) and High Temperature Electrolysis (HTEL). HEROSE offers safety valves for electrolysers of any size.

Storage and pipeline transport

Hydrogen is an energy medium that can be conveniently stored. One possibility is storage in salt caverns. This method of underground storage in large caverns has been used for some time to store natural gas. Compared to above-ground storage, underground caverns are particularly safe and they offer a large storage potential. According to the German government, the potential in Lower Saxony alone for storing hydrogen energy in salt caverns is about 300 billion kilowatt hours. A considerable amount – total electricity consumption in Germany in 2021 was 503 billion kilowatt hours. The underground cavities of the caverns are created artificially, are very deep and have a very tight seal between them and the surrounding rock.

Safety for the operation of caverns and transport pipelines

HEROSE offers suitable safety valves that are specially designed for the hydrogen medium in order to safely operate the caverns and the connected infrastructure. HEROSE offers the safety valves type 06850 for a set pressure between 0.5 and 250 bar and a safe delivery of 5 tons of hydrogen per hour, at 200 bar. For applications with higher pressure up to 550 bar, the valve type 06810 is in the programme. For lower pressures between 1 and 55 bar there is the safety valve type 06012, which, for example, can discharge 12 kg hydrogen per hour at 4 bar. For critical applications, HEROSE offers a safety valve that already opens completely at 105 percent of the set pressure instead of the usual 110 percent – this type 06383 valve is also available for use with hydrogen.

Many existing gas pipelines are also suitable for transporting hydrogen. Before the age of natural gas, the piped “town gas“ product consisted of about 50 percent hydrogen, so many pipelines were designed to transport this medium. In the future, locally produced hydrogen can be compressed and transported via these pipelines. Our valves enable the safe operation of these smaller installations.

High storage density for extended transport distances

Liquid hydrogen has only one fifth of the volume of gaseous hydrogen compressed at 250 bar. Cooling down to -253 ° Celsius is necessary for liquefaction. Liquid hydrogen can also be stored cryogenically at low pressure. Liquid hydrogen is stored and transported in extremely well insulated cryogenic tanks. Due to the reduction in volume, liquid gas storage tanks are well suited for transport over long distances, for example for sea transport on ships.

Liquid hydrogen safety

HEROSE offers cryogenic operating globe valves for the safe control of liquid hydrogen flows. With an operating temperature of up to -269 ° Celsius, these valves easily handle the temperatures of liquid hydrogen: By means of an intelligent modular system, the HEROSE FullX Type 11C01 can be configured exactly to the requirements of the respective hydrogen infrastructure. The FullX has a lot to offer: a variable stem length, flow control by hand or automatically, flow throttling, backflow prevention or a bellow to reduce hydrogen leakage to 10-9 – so that it would take millions of years for 1 gram to leak out. For installation in hydrogen systems, the FullX allows various options: straight, angled or y-shaped – a truly versatile and powerful modular system; it is even suitable for upside-down installation.

From liquid hydrogen back to gas – after transport

When imported liquid hydrogen arrives in Europe, it is vaporised again to integrate it into the gaseous infrastructure, for example, into pipelines. During the transition from the liquid to the gaseous state, the low temperature of -253 ° Celsius and also a very high pressure must be coped with. For this type of application, the high-pressure safety valves such as the 06850 valve can be used at temperatures as low as -269 ° Celsius. This valve is ideal for the combination of extreme conditions such as ultra-low temperatures and very high pressures.

In demand everywhere as a clean energy source

Climate-neutral and sustainable solutions are being sought, especially in energy-intensive industries such as steel production. Thyssenkrupp is on the way to a coal-free steelworks and is planning to use green hydrogen as a source of energy. The first hydrogen-powered Airbus aircraft is still music of the future, but here too the planning goes beyond fossil fuels. The possibilities of converting hydrogen into methanol, ammonia or other chemical forms make the energy source so versatile.

Huge potential – for climate protection and energy transition

The production of green, climate-neutral hydrogen is currently being developed. According to forecasts, this form of energy will remain a scarce commodity for some time to come. However, the start has been made, the technology is ready and the infrastructure is being established. European plans call for the production of green hydrogen to grow to 10 million tonnes per year by 2030. HEROSE is helping to make handling safe and reliable with valves designed for hydrogen.

Three questions for Jurgen Louis, Senior Business Development Manager at HEROSE, who has been significantly involved in the further development of products for use with hydrogen:

Why are HEROSE valves now suitable for use with hydrogen?

Why are HEROSE valves now suitable for use with hydrogen?

“The casting material of the housings has been adapted accordingly for shut-off valves, filters and check valves. For the safety valves, the material for the seat insert has been modified.“

What modifications were made?

“The casting materials have undergone extensive hydrogen embrittlement tests and the composition of the materials used has subsequently been adapted so that the valves are hydrogen-compatible in all circumstances. There is a higher quality material in the area of the inlet bodies of the safety valve for use with hydrogen.“

What is hydrogen embrittlement?

“This is the change in the stability of metals, or more precisely their brittleness, which is caused by the penetration and incorporation of hydrogen into their metal structure. The materials that have been adopted by HEROSE remain ductile and thus durable even under the influence of hydrogen.“

Read the current digital customer magazine now!

Read the current digital customer magazine now!